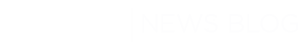

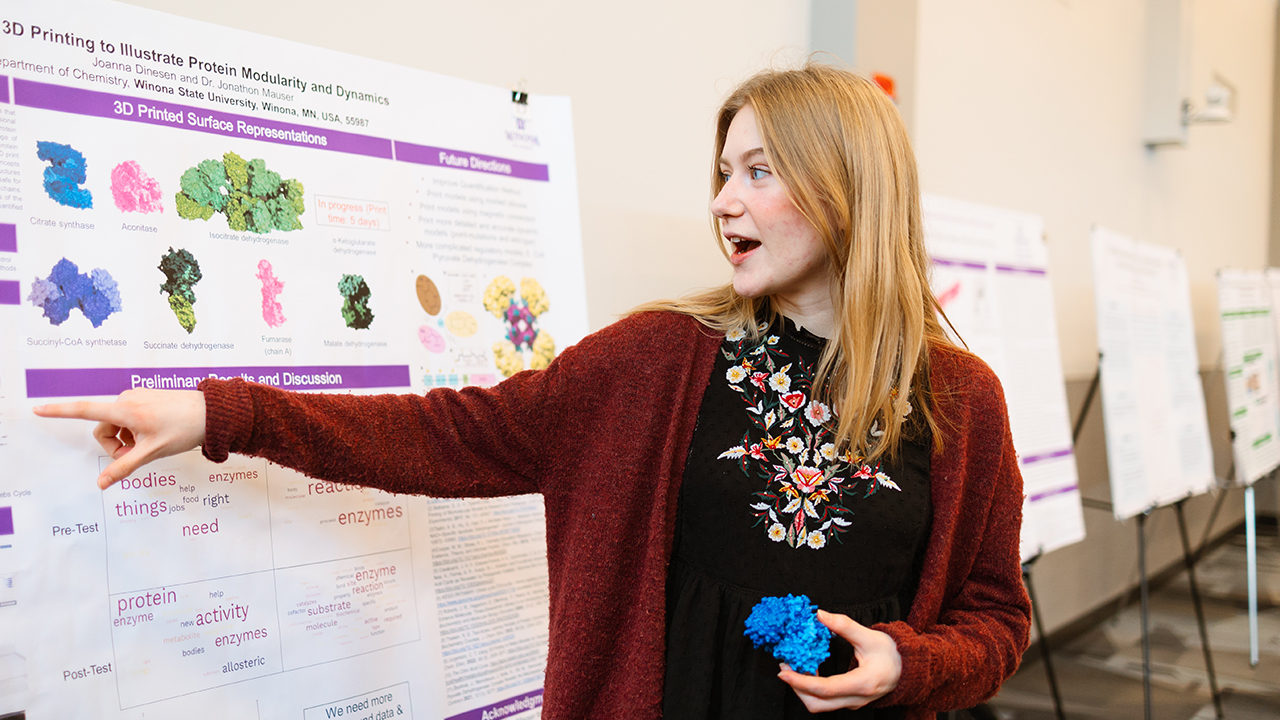

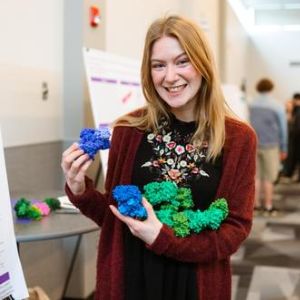

Among nearly 100 students, faculty, and staff gathered in the Kryzsko Ballroom at Winona State University, biochemistry student Joanna Dinesen ’23 stood next to her poster board covered with research information and held out a 3D printed version of a metabolic enzyme to a group of students.

As she handed over a blue enzyme, she explained that some of the 3D models were made to feel “squishy” to show how the molecule moves around within the body.

Dinesen was one of more than 90 different student research projects that showcased their work as part of the Research & Creative Achievement Day during the Ramaley Celebration.

“This is the last stage of the scientific method,” chemistry professor Jon Mauser said, as he gestured to the crowded room of students reporting on their research. “If you don’t communicate your research, it didn’t happen.”

Dinesen said that doing her research project and presenting it at the end helped her to fully grasp the topic she was learning about.

“I learned a lot about them and how proteins work together,” Dinesen said.

It also gave her the experience of working with a 3D printer in an advanced way. To get the “squishy” elements that were needed, Dinesen experimented by creating them with different polymers.

Dinesen, who plans to pursue a career in biomedical engineering, said the experience was valuable in helping her practice skills she’d need in the field.

Getting hands -on experience in a field that students are pursuing for careers was a common theme among research presenters.

Composite materials engineering students Kellie Hardecopf and Alex Klagge said their research project of making a lightweight and sturdy sawhorse gave them the experience of taking a project from idea to creation–and understanding the roadblocks that might come in the way.

While choosing an item to create using composite materials, the five-person group of students did market research and analyzed which item would be the most successful on the market. After landing on a sawhorse, the group’s goal was to make it as lightweight as possible while holding a significant amount of weight.

What they developed was a sawhorse that weighs about 5 pounds less than plastic sawhorses but can hold at least 100 more pounds than plastic ones.

“It should hold up to, or more than, 500 pounds,” Klagge said.

Both students said the hands-on research project gave them more than they could get from textbooks.

The hands-on experience gives you a better understanding of how to create a product. It gives you the experience without it affecting your career.

For Hardecopf, who plans to go into aerospace and defense with her composite materials engineering degree, said doing the research gave her experience in the lab that will impact her future.

“It helps a lot being in the lab setting,” Hardecopf said. “We are always in the lab.”

Beyond chemistry and composite materials engineering, students presented research on topics as wide as there are programs at Winona State. Others included research projects on the death penalty in the U.S., how estrogen levels in water are impacting fish, and how well ChatGPT comprehends word meaning.

“They’re doing stuff that students ordinarily aren’t able to do until they’re in graduate-level programs,” professor Jennifer Anderson said. “They’re learning how to do research.”

When confronted with a problem that doesn’t have a known or easily accessible answer, students are learning how to find the answer on their own, Anderson said.

“You don’t have the answer key in the book anymore,” Anderson said. “And if you do research, you need to be able to explain what you are doing to the general public so that they can understand it because they are who likely paid for it.”